By combining the best of both worlds - Kiss-cutting on the S Class OPOS CAM roll cutter and Thru-Cut on the F Series flatbed cutter - significant performance increase can be achieved.

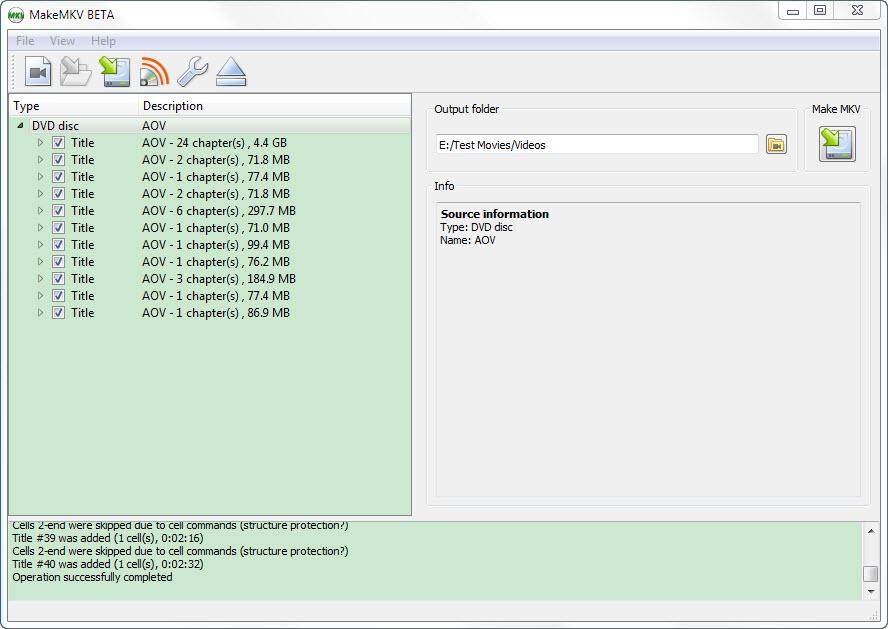

Thanks to intelligent camera recognition technology, jobs prepared for the Summa F Series flatbed cutters can be run on the roll cutter OPOS CAM units.

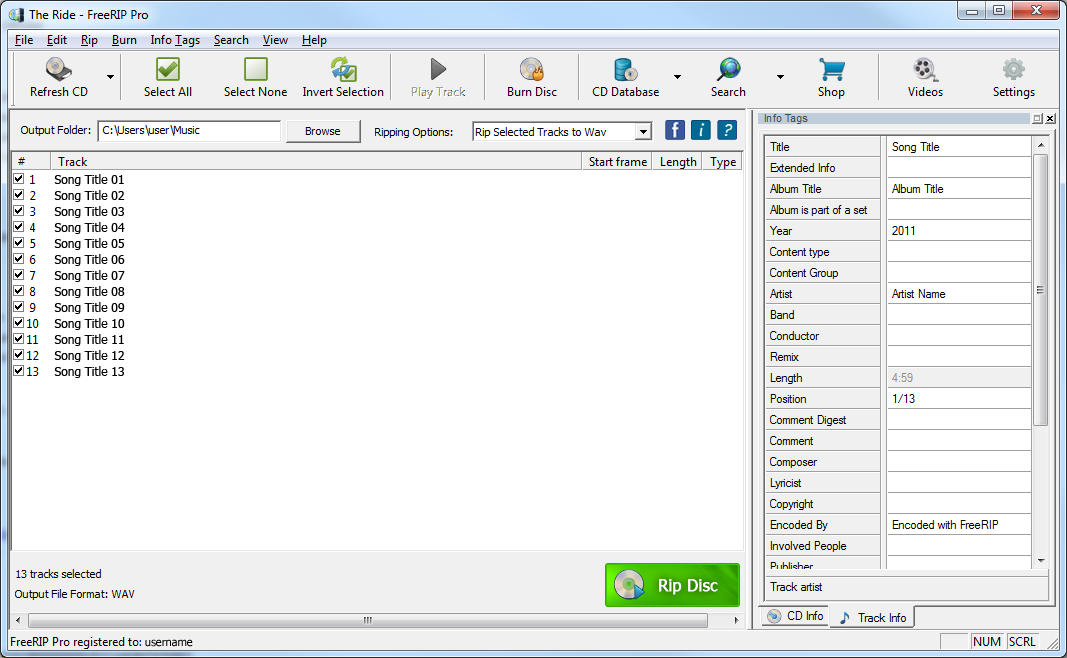

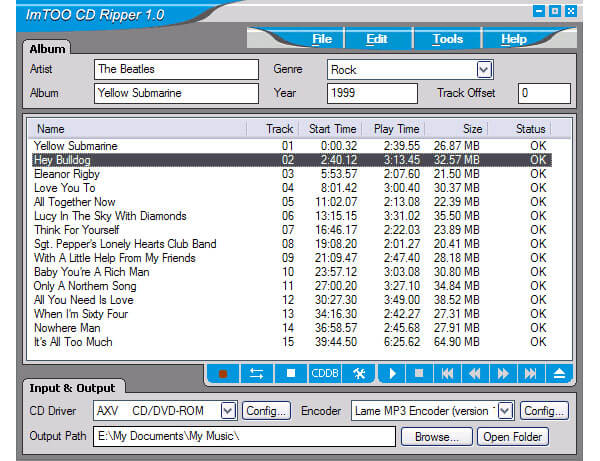

The advantages of a Twin workflow are multiple: With GoSign a Summa S Class 2 roll cutter with OPOS CAM can be controlled in the same way as an F Series flatbed cutter. Because in this case, the plug-ins cannot be used. This hot folder system is specifically useful when the design software is located on another computer in the network. The flexible action sets ensure that what happens next is fully customisable. With the hot folder functionality, files dropped in a folder can now also be opened automatically in GoProduce. Not only is GoSign able to import jobs by means of file selection, a hand scanner or OPOS Barcode (see further). A small mistake in these files could only be solved by reprocessing the entire job. Normally these files can’t be edited anymore. Import of Plot files GoSign 2.0 can also import plot files, which are files prepared to send directly to our cutting equipment.

Hot Folder job handling to automatically send cutting files to the Extended import of plot files such as DFX and PLT files, as well as files from free open source programs. Barcode functionality to ensure plot files can still be modified to optimise cutting requirements. GoSign Pro Pack embeds the before mentioned features and more: Twin Workflow to increase production speed and efficiency by combining a Summa roll cutter and a Summa flatbed cutter in one single workflow. The optional Pro pack offers even more functionality for those businesses wanting to maximise the use of their cutter. The software GoSign that comes with the machines includes plentiful useful features to get you going and will expand further in the future.

0 kommentar(er)

0 kommentar(er)